Similar Posts

Stretching a Canvas

An artist in my circle wanted to make a frame on which to stretch a canvas. The joint in the corner of such frames is a complex thing that is not to be tackled by a beginning woodworker. I needed to simplify it. In the hope that beginners will give it a go I have…

Wooden Cake

How can a woodworker be involved in cake decorating? My wife is a traditional cake decorator. She does the fancy thing with icing and makes sugary lace and that kind of stuff. An event called for an art deco cake. It could have been made from icing, but in that era much of the furniture…

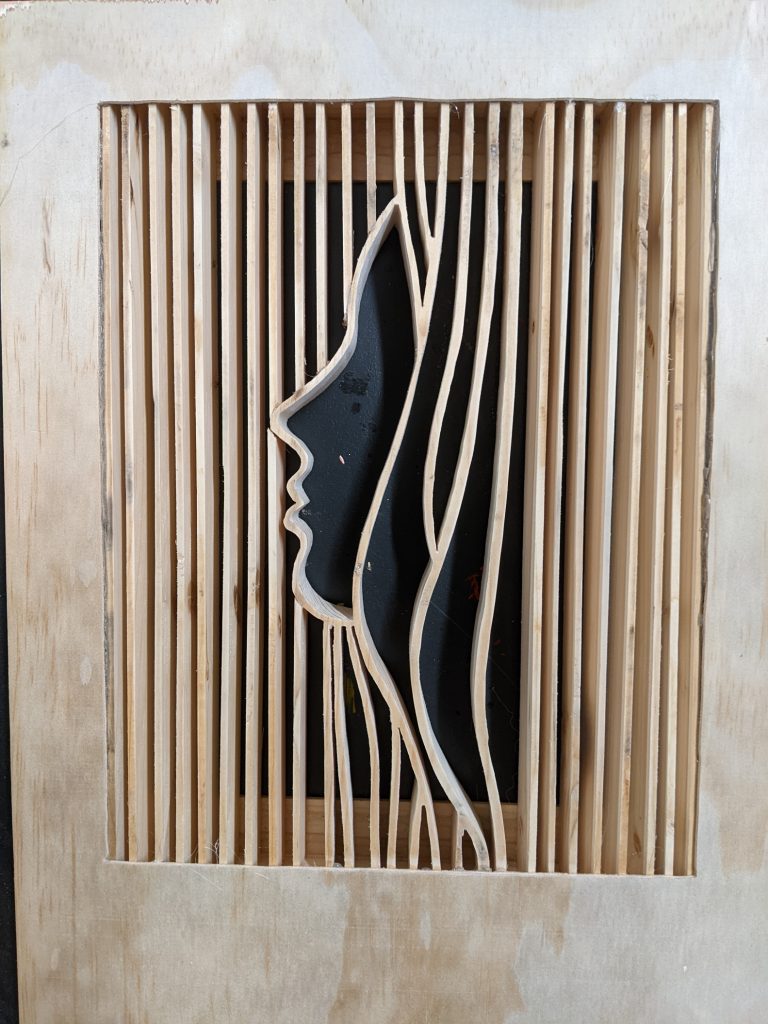

Grille

After a few attempts to bend fine strips into curves, I gave up and resorted to the scroll saw.

Wooden Easter Bunny

There are versions of this on ETSY and Thingiverse and probably many other places. I couldn’t find anywhere that seemed like an original source. My whole family are all getting one. They will love it because it is from my hands.

DIY Simple Chisel Plane

Wooden hand plane aficionados (ambiguity intentional) make much of the fact that they can use words like “frog, cutting angle and throat” with confidence. That confidence is proof that they must be experts! If you add complexity to the activity then great reverence must be assumed. Much is made of achieving chisel cuts at particular…

Note Pad

Our shopping basket seemed to take foreverrrrrr to finish, but that was only because a few of my disabled friends renewed their love for sanding and painting. It was a good thing, for the results were so good we decided to give the baskets to our mothers for Mothers’ Day. But it wasn’t quite Mothers’…