Not a Roubo Bench- workbench for a small space

A workbench is a personal statement. In a concrete way it expresses needs, resources and interests of the person who made it. Many boasts are to be found that an author/woodworker has intelligently created superior responses to the needs of a workshop. Here is another entry into that crowded arena. However, what follows makes no claim to superiority or originality.

|

| Dimensions were dictated as much by the size of scraps as by recognition of standard working heights |

This blog entry is a response to personal engagement in woody things. Paramount is time in a wood tool shop where conversation is always exploring wood related topics. Some customers seem to have no shortage of money or square metres. But… we also sell into tiny workspaces where the driving force is a passion to do woodwork. Dollars may or may not be an issue, but square metres are in short supply. It is this second group of customers who engage me in fascinating conversations about how they squeeze three litres out of their two litre sheds. These customers are my inspiration in this project.

|

| These little drawers recycled some scraps of Baltic pine. Because I couldn’t find eighteen matching bolt heads in my random collection. It was a philosophically challenging moment! |

My bench combines an extensive knowledge of resources available in the tool shop. Impetus to begin the project arrived in the form a load of discarded decking timber , 30mm thick. It looked just right for a small bench top. And, just like many customers, I love free stuff.

Work Surface

Laminated sticks of used hardwood, glued with epoxy, are the crown of this bench. Lots of damage had to be hidden by carefully arranging boards. Where damage couldn’t be hidden repairs were undertaken by drilling a clean hole and gluing in plugs. Hardwood makes a robust bench because it can take a beating. Another school of thought is that a work surface should be soft like pine because that is less likely to bruise a dropped work piece. My experience is that lumps of dried glue are more dangerous than hardness of the timber. This bench will be given a wipe over with shellac to make it look good. But, more importantly, there will be a light coat of wax to discourage glues from sticking or at least make lumps easy to pick off.

|

| The vice manufacturer installs a little plastic dog. It is not really strong. I replaced it with wood, knob and propeller nut. |

Work Holding

Much is made of the superiority of traditional vices and enthusiastic sentimentality is squandered on wooden threads. For me, a reasonably priced lump of cast iron with a steel screw will do. The vice I found has a little dog thing that rises and falls to use in combination with bench dogs. An 80mm thick bench is prime real estate for bench dogs.

Portability

Scarce space in a small workshop is better exploited by facilities that are portable. But, a good workbench has significant inertia and is difficult to shift. I hope that I have solved this conflict with a mobile base that is normally used for a machine. This base is rated at 650kg.

|

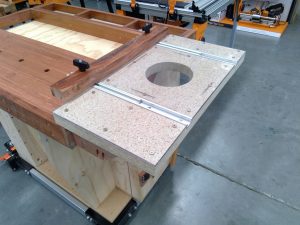

| Bits of aluminium extrusion fit neatly into each other. This combination can take a standard 3/4 mitre gauge and still be used to hold a T-bolt. |

|

| These scraps beneath are screwed and glued in place and are the means by which the router table can held in the vice. |

Router Table

A router is a good tool for a small workshop. Exploring that possibility is one of my aims in this project. My attempt relies on making a router table small enough and light enough to be portable and easily storable without requiring either heft or hernia.

Beneath the Top

My work beneath the top is a little self indulgent. I have done things I enjoy rather than obsessively save cubic measurements. For instance, I enjoy the technique of making a box and cutting off the lid, that’s the tool and router bit storage cupboard. Plywood units have been butted and screwed. Each was a frivolous, simple enjoyment. My aim was to work quickly so that I didn’t have to wait too long to see how it came out. Fun is a major function of my workshop. Dimensions were dictated by what could be conveniently cut from the recycled timber. In fact, my most valuable measuring tool for the whole job was my eye!

Materials

Cheap!! Wherever possible, I have used reclaimed timber: pallet wood, rescued Baltic pine from a demolished 1920’s house and old decking boards. Plywood is new but in offcut sizes.

New Stuff

Hardware is from the shop. Installing it helps me talk with better personal knowledge to customers.

|

| An old leather belt makes a great chisel rack. My grandpa had one in his shed and I had never made one until now. But I have to thank him for putting the idea in my head 55 years ago. |

Conclusion.

The great bench god, Roubo, has generated legions of bench making disciples. Their work is obsessed by emulations of their leader. I am sure that, for Roubo, the bench was heuristic, its value was in what it could facilitate and not in itself. Cutting a 2 inch diameter thread in wood may be a noble aim, but if it becomes an end, and not a means to an end, then the family’s new furniture will never happen! Imported cast iron can start to look good because it lets me get on with the job sooner. My constant exhortation to woodworkers is to keep playing the game. Allowing the minutiae of internet wisdom to take control becomes a complex brick wall and a barrier to work.

|

| A really crappy and small hand plane, I think it blade was made from compressed dog food tins, supplied me with handles to hang stuff on. |

Get a goal in mind; find some wood; make some plans and make some more up as you go along. If things go awry, its only a bit of wood. It is only a failure if you stop trying. If the aim of the game is to be woodworking, then every splinter is a success. Bruce…