Candle Sticks

Candle Sticks

These candle sticks are my response to a gig at a conference for intellectually disabled people, Having a Say.

Our activity was to involve ten attendees and their helpers. There were no requests for my work to follow any themes. Attendees could be dexterous, or not. Helpers may be anything from ex-tradesmen to multi-thumbed demolishers. I had no way of predicting the abilities I had to engage or the level of help available. It was difficult to know where to start. The open brief seemed to need multiple projects with activities varying in complexity.

Each project needed to be sanded and lacquered. In an ideal construction we would sand the pieces before construction, then glue them carefully. Pragmatically, however, I use sanding and painting to busy the hands as I circle around my friends. This may compromise the woodwork, but the activity is more about the making than a final product. And, proudly, we managed to send each of our woodworkers home with a cool candle stick they had made themselves.

Design One

Valentines day wasn’t far away, so a bit of kissy stuff was appropriate.

This was the least daunting of the three constructions, we:

Painted the silhouette,

Glued the silhouette into the slot, &

Screwed a brass cup into the hole.

Note- A scroll saw with a coarse blade was used to cut plywood stacked in ten layers to quickly make the silhouettes. I cut the slot with a biscuit jointer.

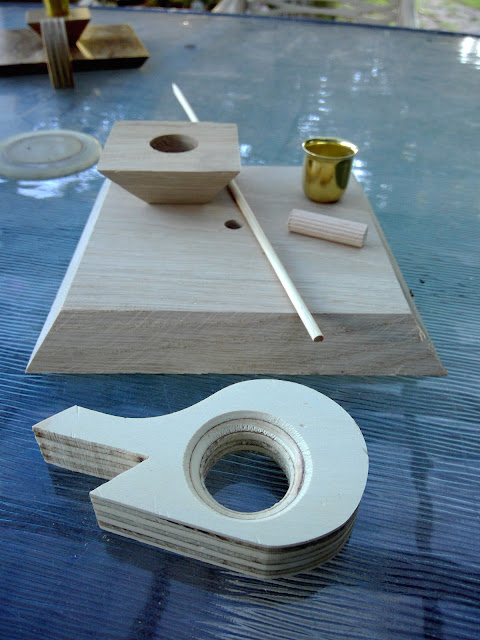

Design Two

This work was great for skilled bashers. Its three pieces are hammered onto a dowel. Holes are 9.5mm the dowel is 10mm multi-fluted. I choose fluted dowel because it hammers in a little easier than straight sided stuff.

The process was:

Bash three pieces together, &

Screw a brass cup into the hole.

Note- It is hard to find thick boards, so the large chunk in the middle was fabricated from two identically shaped pieces glued face to face.

Design Three

Delicate bashing and accurate drilling were required.

The piece of dowel is short and likes to wobble as it is bashed. Fixing the handle called for a tiny dowel (satay stick 4.5mm dia) hammered into a 4mm hole.

The process was:

Bang the base and middle together,

Glue and clamp the handle into place,

Drill a 4mm hole through the handle into the base,

Bang in a satay stick to lock the handle in its spot, &

Screw brass cup into the hole.

Note-The handle consumed a lot of time and energy. Its shape took me a long time to settle on. Then the act of cutting it out could only happen one at a time.

A personal reflection. What a day I had! Teaching is sharing! At session’s end, every conference attendee had a candle stick, and every helper had discovered something new. It was a reminder of the many layers of a lesson and how people access only the layers they are ready for. Finally, this session caused much nervous energy on my part and I probably did four times the preparation needed. But, I too, took away lessons from the layers that I accessed.