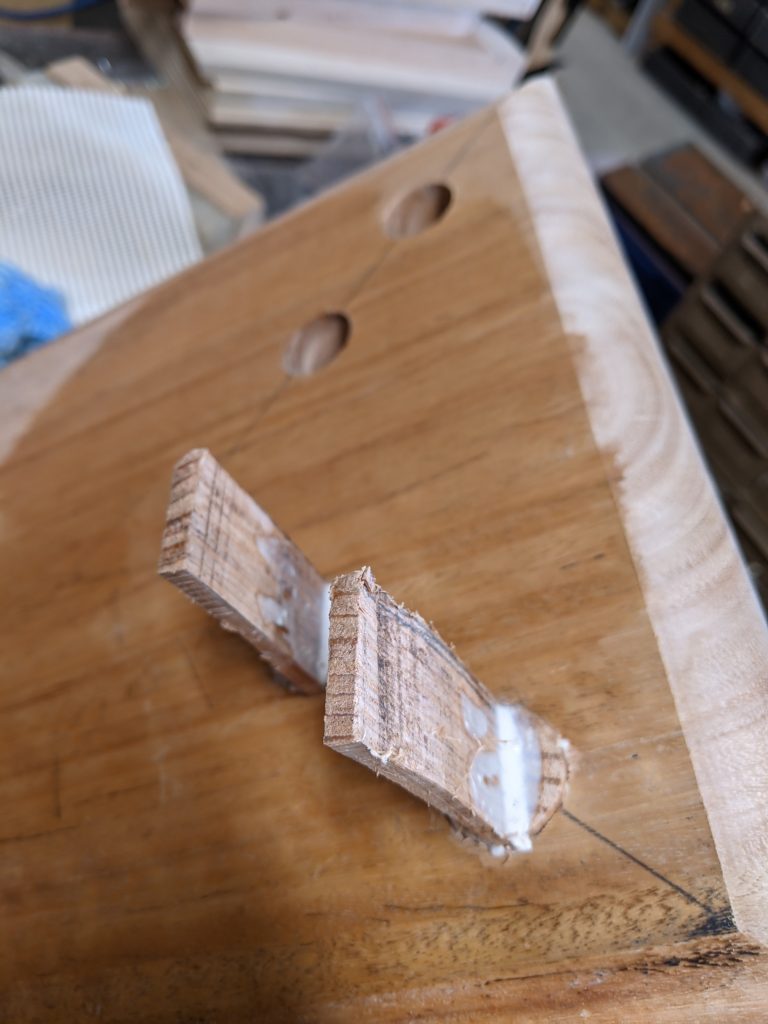

Blackbutt Scrap

Sometimes a piece of wood is too good to throw away. Here is the end result of pushing a piece of blackbutt from one end of the wood rack to the other for about three years. It coincided with the acquisition of a long plug cutter.

A cheap but long plug cutter.

These tools can cut plugs over 100mm long, that is complicated when the drill’s quill only travels 75mm but it still expands opportunities to explore long round tenons.